PAMA, con un’esperienza di quasi un secolo e ad un reparto di ricerca e sviluppo che costantemente studia e lavora su nuove tecnologie,

sviluppa e costruisce alesatrici, fresatrici e centri di lavoro per diversi settori ai quali garantisce qualità e affidabilità.

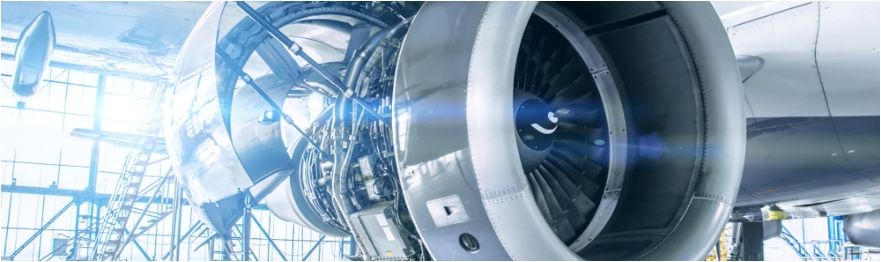

I NOSTRI SETTORI

CHI SIAMO

Your solution provider

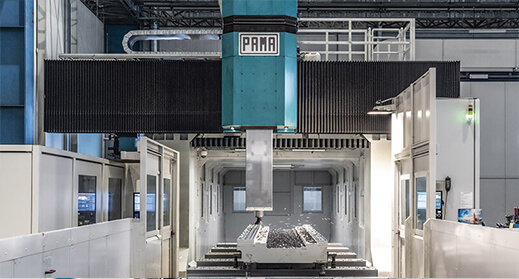

PAMA è un’azienda italiana presente sul mercato delle macchine utensili da oltre 90 anni, nota per costruire unità di grandi e medio-grandi dimensioni, ben apprezzate in tutti i settori in cui sono richieste massima rigidità e alta precisione.

PAMA si è imposta a livello mondiale per la tradizione, l’alta qualità e l’eccellenza tecnologica dei propri prodotti.

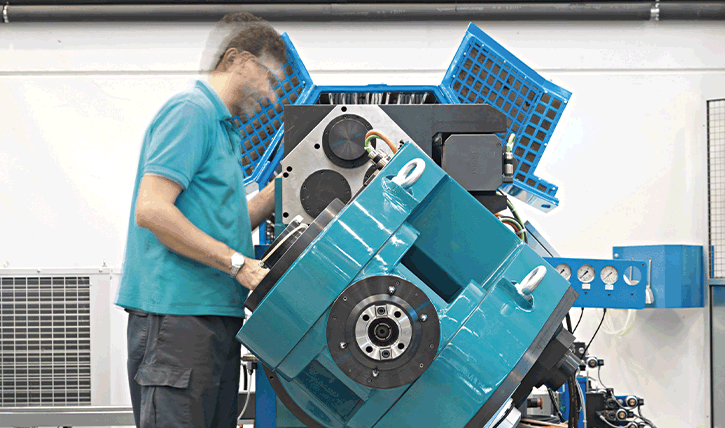

SOLUTION PROVIDER

PAMA al servizio e al supporto del cliente per soddisfare tutte le esigenze anche nelle più difficili applicazioni delle macchine utensili.

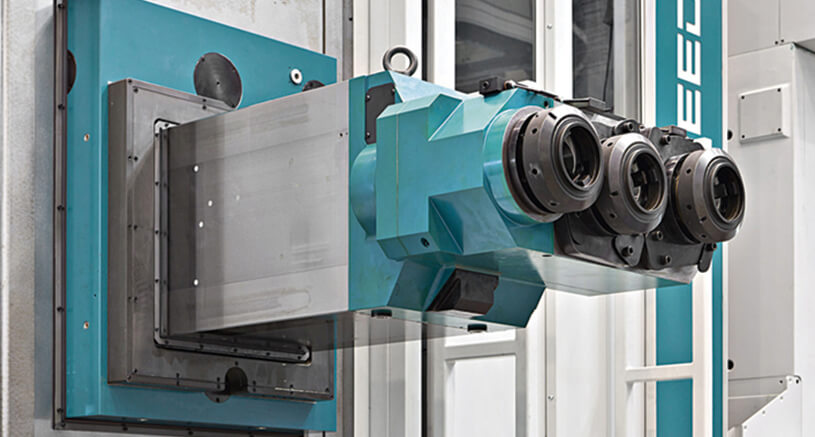

PAMA, MACCHINE UTENSILI CUSTOM

PAMA personalizza le proprie macchine utensili e studia servizi tecnologici dedicati per proporre al cliente la migliore soluzione e per soddisfare anche le esigenze più complesse.

I NOSTRI PRODOTTI

Le macchine utensili PAMA permettono di eseguire con precisione e rapidità lavorazioni di

alesatura, foratura, fresatura e tornitura, soddisfacendo le richieste dei clienti anche nei settori più

esigenti.

ASSISTENZA

Service

PAMA vanta una lunga esperienza nel campo delle macchine utensili e fornisce ai propri clienti una gamma ampia di servizi e contratti per garantire inalterate nel tempo le alte performance dei propri prodotti.

Dall’assistenza telefonica alla diagnostica remota, dalla manutenzione preventiva all’ottimizzazione della geometria della macchina, con PAMA la vostra macchina è in buone mani.

La filosofia di PAMA si basa sulla vicinanza al cliente oltre che sulla tempestività e sull’efficacia dell’intervento per fornire il massimo supporto

HIGHLIGHTS

Attività, news, eventi: gli ultimi aggiornamenti dal mondo PAMA.

FIERE ED EVENTI

Siamo lieti di invitarvi alla prossima CCMT 2024 per farvi scoprire le nuove soluzioni e tecnologie di PAMA.

FIERE ED EVENTI

Siamo lieti di invitarvi alla prossima IMTS 2024 per farvi scoprire le nuove soluzioni e tecnologie di PAMA.